Build Log: ACNH Happy Home Academy Plaque

Nintendo recently released a big update and new content for Animal Crossing: New Horizons, so I’ve been sucked back into the game and decorating my home and island. That got me thinking it would be fun to make myself a Happy Home Academy plaque for my real home! This would be a chance to make some simple molds and have fun with cold casting.

I started with the plan to 3D print the face details, make molds with brass or gold metal powders, and laser engrave placement for everything into a wood plaque.

Photography Time

To get started, I had to snag a few screenshots. The update made this simple with a new “handheld” mode for the in-game camera phone that lets you snap photos from your character’s perspective. I placed the plaque at eye level and took a few photos to get an idea of the size of the plaque and capture the details.

Next, I needed to nail down a few details, like the measurements and what the signature at the bottom is supposed to be. The measurements were easy. The plaque seemed to be about the size of my character’s head, so I roughly measured my own head with a tape and figured the plaque would be about 9.5” tall. I opened the screenshot in Photoshop to resize the image to match. To my surprise, the screenshot was already about the right size. I made a box that was 9.5” x 8” and the plaque was only slightly smaller. I assumed the plaque would be as thick as the plaques I had in on-hand, about 16.75mm.

Plaque with the Properly Sized Bounding Box

The text at the bottom was more difficult to understand. People of the internet have tried to determine what it is and there are two dominant theories. One theory is the text is “Academy,” but the cursive lettering doesn’t match very well. The cursive does appear to match “Sunday,” the day you receive your HHA grade and applicable plaque in the game.

I wasn’t happy with either of these options. A real plaque would probably include information-e.g., the HHA rank, score, date, or the recipient’s name. I chose to redesign the bottom to include my name or a space for a metal plate.

Photo to Vector

I used Adobe Illustrator to trace the plaque’s shape and face details before importing the SVG into Fusion 360. I did it this way so I could draw the inner shape of the plaque and then use Illustrator’s Offset Path tool to create the outer edge. I found this easier than trying to do everything in Fusion 360.

I also added a 10” x 10” bounding box so I could be certain the design was the correct size after importing it for the laser or Fusion 360.

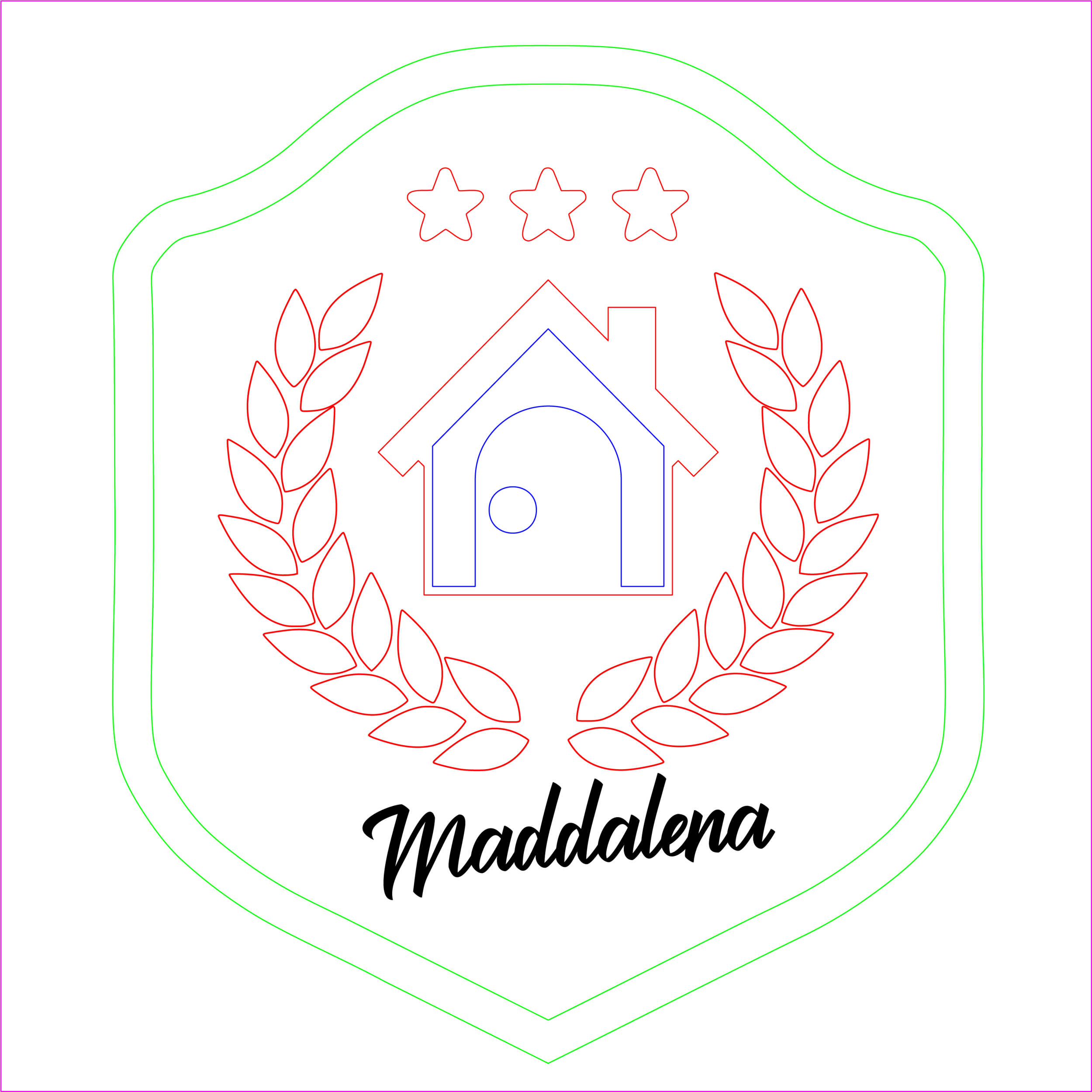

Near Final-but Flawed-Vector Design

I added my name at the bottom as a placeholder while I determined what I wanted to put there. The SVG was almost done, but there was an issue: the outline of the plaque was too complex.

Sometimes you import an SVG and Fusion 360 will choke the moment you ask it to extrude a section. In my experience, this is often caused by very complex vectors. My outline of the plaque’s shape was complex enough to make it impossible to work with inside Fusion 360. I used Illustrator’s Simplify tool to reduce the number of points.

Tip: If you highlight your vector graphic and have tons of little points, Illustrator can simplify the design. Select your graphic (or the complex paths) and then go to Object menu, select Path, and then the Simplify… option.

Remember, simplifying does tend to round corners. I had to go back and readjust the above version because I simplified everything instead of just the plaque outlines. That was mostly fine but it decimated some curves and corners that were really necessary for making this a 3D model. For example, the simplification made the stars ever so slightly non-uniform and rounded the interior corners. They looked fine at a glance, but the geometry didn’t work for what I wanted to do in Fusion 360 (e.g., tapering the shapes).

Taking 2D to 3D

After some tweaks, the SVG was done and provided everything I needed to make the 3D model. All I had to do was import it and extrude the sketch elements, but first I had to make sure it imported with the correct scale! I follow AutoDesk’s suggestions for how to do this.

First, I imported the SVG, placed it, and measured the lines of my bounding box. They were supposed to be 254mm (10”), but measured at 190.503mm. When divided, these measurements showed the SVG needed to be scaled 1.33x (actually 1.333312336288667… but one can be too precise). I removed the SVG and placed it again with that scale. That gave me a properly sized sketch.

First, I extruded the whole sketch to make the base plaque. I extruded everything -16.75mm. The negative number made it so the body extruded below my sketch and the sketch elements remained on the top face of the new body. Little things like this helped me manage the design and keep everything straight in my head.

Then I cut out the outer area of the plaque and added a fillet where the front of the plaque met the back. This created face of the plaque and the curved dip down to the base.

In case I ever wanted to 3D print a whole plaque, I cut 1mm slots in the plaque body for all of the face details and then extruded all of the details to be 3mm thick. Each piece would extend 2mm from the face of the plaque.

The stars are curved on the game model, so I tapered the extrusion to match. To make sure they wouldn’t curve below the surface of the plaque, I extruded the stars to be 2mm with the taper and then extruded the bottom of each star 1mm into their recesses.

The Final Render of the Plaque

This way the pieces could be printed separately and dropped into the slots in the plaque. This also made sure the pieces would fit properly into engraved wood.

The plaque could be easily printed in multiple colors using a basic color swap at 16.75mm or printed separately and assembled with a little glue.

At this point, pause and appreciate that a 3D model became a 2D picture, a 2D vector, and then became a 3D model once more. Prop making can be funny.

Testing the Models

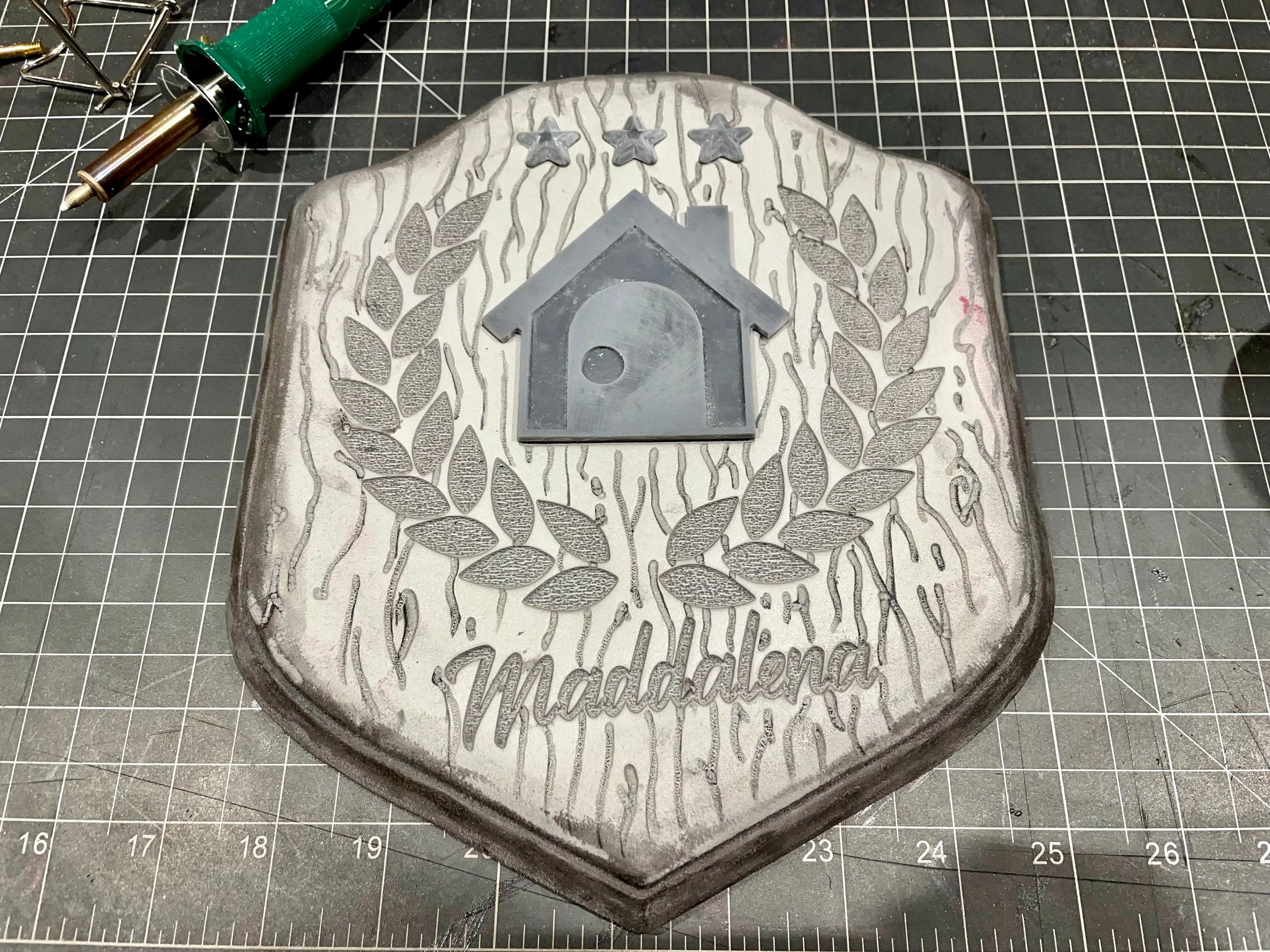

Engraving and Fit Test with an Initial Version of the Laurels

I printed the pieces in resin to capture the sharp corners of the house and reduce the prep work for the molds. I printed all of the laurel leaves individually. I could have printed and molded just one, but I wanted to make a gang mold (a mold that can create multiple copies at once). The idea was to be able to cast an entire plaque with one resin pour.

As discussed in Printing Props, I did a test assembly before proceeding. First, I found a shield-style plaque on Amazon for $12. I couldn’t find one that matched the shorter (kind of squished) shield of the in-game model, but the one I found looked good. I only cared about the dimensions being close to my design so I could test engraving everything and see how it all looked.

It would have been awful to have created a custom plaque out of a nice hardwood, engraved it, and then learned it didn’t work with the 3D printed pieces!

I prepared the SVG for the laser by checking everything against a centered line. “Measure twice; cut once” applies to vector files and lasers, too! Sure enough, I learned a few things had drifted slightly out of whack during editing, so I re-centered everything.

The printed pieces fit well inside the engraved areas. The fit wasn’t perfect, but there were some knots or sappy sections of wood that hadn’t burned evenly. I felt alright proceeding with the plan. My chief concern at this point was material shrinkage. The final resin pieces could shrink enough to affect their fit. All resins do not shrink equally or 100% consistently.

If I had a CNC machine, I would have used that instead of the laser. A CNC would be the best tool for this job, really. It would be able to cut and shape a plaque out of wood stock and create the recesses for the face pieces.

The resin I tend to use (Prusament and Siraya Tech) seem to shrink about the same as Smooth-On’s Smooth-Cast 326, so I felt confident the final pieces would work. I’d have the test engraving to do another fit test before trying to create my final plaque. If the pieces didn’t fit, I could scale the vector file for the laser to account for shrinkage before the final. Again, it’s important to test everything before rushing ahead using more expensive materials.

Inspiration Strikes

I had set out to make a wood plaque, but I had some new tools for foamsmithing and decided to try making the plaque out of EVA foam. The in-game plaque looks like nicely finished wood, but I thought it would be fun to make a plaque that embellished the general cartoonish nature of Animal Crossing. I decided to make the plaque out of EVA foam and carve wood grain.

I returned to the SVG and added an offset path to the interior of the plaque (-12.7mm). Then I cut out three pieces of 6mm EVA foam:

1 x Back piece

1 x Middle piece with the center cut-out

1 x Front face

I dropped in a laser-cut piece of 6mm hardboard into the center to reinforce the foam and add some rigidity. That is why I used two 6mm pieces for the back instead one 10mm piece of foam. The hardboard core also provided something that could take a screw for a sawtooth hanger or something similar, if I ever wanted that.

You may notice 3 * 6 does not equal the planned 16.75mm thickness, but the plaque felt right in my hands.

EVA Foam Base with Hardboard Insert and Score Line to Line-up Top Layer

I used SKS Props HD Foam. It’s generally awesome stuff, but I have found it works the best of any EVA foam I have tried with a laser. Once I had everything cut and engraved, I glued it together with Barge contact cement.

To create the curved transition between the top and bottom, I filled in the seams with Gap Filla by Prop Monkey and used a rounded silicone make-up brush to create a smooth curve. Once that dried, I got to use a new tool: a 45° beveling tool for my rotary tool made by Arcane Armoury. The side view of the in-game model looked like it was curved from the front face to the back, so I beveled all of the edges and then smoothed the corners.

A laser can engrave EVA foam so well that it creates recesses that are as good as a CNC. It’s just foam instead of wood, so I’d have to do some additional work to sell it as a wood plaque from the world of Animal Crossing. The downside of the laser engraving is the engraved surfaces of the foam are very much not smooth, so if it’s exposed as part of a prop you have to fill it with something like foam clay, Gap Filla, or another body filler. In this case, the rough surface worked in my favor because it provided something for the glue to grip for a strong bond later.

I carved in wood grain using a wood-burning tool. I had always drawn a design, scored it with a craft knife, and opened the lines with a heat gun, but I really wanted to try this method. I used a blunt tip to trace the grain and create some even valleys, "knots, and small holes. Once finished, I heat sealed the foam and coated everything in Plasti Dip.

Making the Molds

I considered how I would have to glue down 36 laurel leaves, decided that sounded awful, and came up with a 3D printed solution. I bought an 8” cardboard tube from the hardware store (the sort meant for cement posts). When placed over the foam plaque, the tube covered the face details with ample room on the sides, so I modeled an 8” circle below the laurels and joined the bodies. I printed the whole thing in ASA and enabled ironing on the topmost surfaces (the front of the leaves) in my slicer.

Ironing smoothed the most-and most important-surfaces of the leaves and letters, so I had to do minimal clean-up. I didn’t bother sanding the sides of anything. That meant some layer lines remained visible from the side, but they’d be difficult to see even up close on the finished plaque. There was no reason to spend time sanding the sides of 36 leaves when only one side of 18 leaves (the outside) would really ever be seen. Not to mention, 2mm is very small, so you’d have to get really close to see any visible lines in the castings.

This gave me an 8” circle on which the cardboard tube could sit. Voila! A mold box. Hot glue sealed the edges and attached the house and stars printed in resin. Then I poured Mold Max 29NV into the box and let it sit overnight.

The mold came out well. My one concern was some of the walls were thinner than I would have liked because I didn’t bother to adjust the layout of the laurels. In reality, the laurels were fine, but the name was much more problematic.

I dusted the mold with brass powder and mixed equal parts brass powder and Smooth-Cast 326 parts A and B. I chose brass because it’s what I had available and polished brass fit the bill as much as antique gold. As an alternative, I could have used some gold leaf, a technique I have wanted to explore for some time. I thought applying leaf to so many little bits would have been really tedious.

I let the mold sit overnight to allow the resin to fully harden. The pieces were only 3mm thick and thinner pieces take longer to completely cure. Once de-molded, I had to clean up the back of each piece.

I made an open mold, so I had to pour resin slowly and try to cut it off before any of the cavities overflowed. Some of the pieces got a little too much resin and were slightly thicker and domed on the back and most pieces had a small amount of flashing on the edges. My rotary tool made quick work of these features.

The same rotary tool buffed the brass powder coating with an abrasive buffing wheel. I used a black pad, about 400 grit, and let the speed of the rotary tool do the work while I lightly touched the surface of the parts. I didn’t want to rip through the powdered surface but buffing with steel wool might have applied too much pressure to high spots and edges on these little fiddly pieces. The powdered coating would be much shinier and provide a nicer finish than the powder mixed into the resin, as long as I didn’t rub it away.

Troubleshooting

My initial casting attempts were disastrous. For my first try, I dusted the mold and poured in a resin mixture that only included the excess brass powder I shook out of the mold. When the resin kicked, there was a severe reaction where the resin met the brass powder and silicone. The castings looked like swiss cheese.

Store Bought Silicone (Left) vs. Mold Max 29NV (Right)

I encountered this sort of thing earlier this year with several different Mold Max 29NV molds and I have reached out to Smooth-On to determine the reason, but I don’t have an explanation yet.

The issue looked like severe bubbles caused by moisture, but I tested the same process with one of Evil Ted’s silicone molds purchased from a craft store. I mixed a new batch of resin, dusted both molds with brass powder, and poured. The same reaction occurred with my mold while the Evil Ted casting turned out fine.

I resolved this by following Smooth-On’s guide to cold casting and mixed an equal part of brass powder in with parts A and B (1 Tbsp of each). Following directions seems like an obvious solution, but I have avoided this in the past to save the expensive metallic powders. However, I made those molds with Mold Max 30, so all signs point to Mold Max 29NV causing a funny reaction when cold casting powders are involved.

Final Assembly

Before I could attach the individual pieces, I had to paint the plaque. I wanted to match the reddish color of the in-game model but personally preferred a darker wood. I used Liquitex heavy body acrylic burnt umber (sort of a dark or walnut brown) as the base and got it into all the details. Then I applied more reddish browns, raw and burnt sienna, over the darker brown base. I used a light touch and some dry brushing techniques and let the surface texture pull the paint off the brush.

I finished the paint job with a few highlight passes with the burnt sienna. This pass gave the edges and high spots a more prominent reddish color. The last step was a top-coat. The in-game model is very glossy, so I tested some high-gloss finishes on scrap pieces.

Smooth-On recommends using a semi-gloss acrylic coat of some kind to protect the metallic finish from oxidation, so I paused to use some of the failed castings and foam cut-offs to test what it would look like if I coated everything in a gloss top-coat.

I didn’t want to go through all of this trouble for a real metallic finish only to fumble the top coat and make it all look like a bad paint job.

I settled on applying Alclad Aqua Gloss to the plaque alone. I applied several coats until I was happy with the overall shine. Then I inserted each of the pieces with a bit of Bob Smith’s Maxi-Cure CA glue. The Maxi-Cure is thicker than the Insta-Cure that I usual use and stayed where I put it while I lined up each piece.

Before I inserted the house and stars, I added some dry-brushed highlights with Liquitex heavy body acrylic iridescent bright gold. The iridescent bright paints are thin and meant to be mixed with other paints or used to add a subtle shine. The effect was indeed subtle but made a big difference. It really helped sell the polished brass as an antique gold. The laurels got the same treatment after they were glued down.

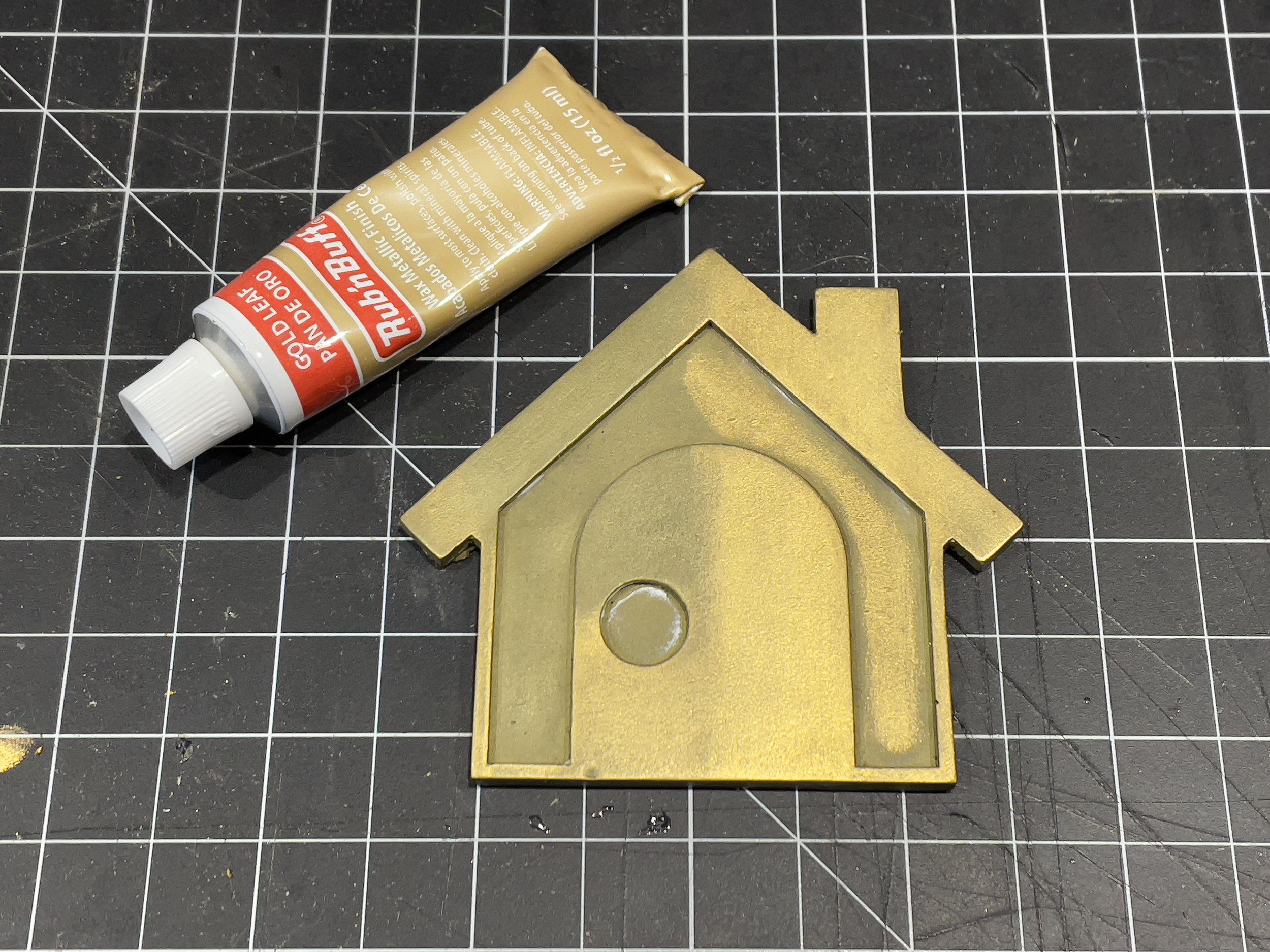

Dry-brushing Gold onto the Brass

At this stage, I learned the name plate was too fragile. I managed not to break it while sanding, cleaning, and polishing the piece, but it eventually broke when it fell off during a test fit. The first failed casting had ruined one of the thinner walls, so making more would have been more painful than using one of the resin prints I had.

Some Thinner Walls Had Some Tiny Bubbles or Gaps that Made Those Walls Very Weak and Hurt the Surface Quality

A backup print replaced the broken piece. I painted it using Alclad II Polished Brass lacquer so it would match other pieces. I hit the edges with a little Pale Gold lacquer and really liked the results. When the light hit the painted surfaces from the side the name shined a brighter gold color but still matched the brass-coated pieces when looked at head-on.

Sunday Arrives

The next day the paint was dry and the name was ready to be attached. It was a Thursday, but I finally had my finished plaque. However, it would be a few more days until the gold sawtooth hangers I ordered would arrive.

The hangers arrived on Saturday. I attached one to the back of the plaque with 8.6mm gold wood screws. For the fun of it, I left it alone until the next day. As in Animal Crossing, when Sunday morning arrived, I collected my plaque and put it on display.

The Final Plaque Before Any Modifications

This was a fun project. I really enjoyed experimenting with engraving EVA foam to accept resin inserts. I expect I’ll do this a lot more in the future to hide seams or give them a different look.

I wasn’t completely satisfied with the brass powder and might revisit this project down the road if I ever find myself with some gold powder or leaf. The problem was the brass powder lost some of its brilliance and shine once the plaque was on a wall and out of direct light. The beauty of making molds is I can jump back into this project at any time and have a set of new parts with just a few minutes of work!

In the meantime, I picked up some gold leaf Rub ‘n Buff metallic wax. This stuff is great for adding metallic accents to the edges and details of props. I’ve had the same tube of silver Rub ‘n Buff for almost five years and I’ve used it on dozens of projects. I almost never use it for its usual intended purpose, completely covering something to make it look like metal. It’s often advertised with examples that show it covering picture frames and various small items to transform wood or plastic into something that looks like metal. I decided to try that with the resin pieces. I had plenty of bad castings to test with, so I started there before buffing the final pieces.

Testing Run ‘n Buff Application Ideas

I used a soft cloth and a very light touch to add a thin layer of wax to the edges and high spots of the face details. The buffing wheel created an uneven surface on the resin parts. The scratches weren’t deep, but just enough to create texture. The light application didn’t get the wax into any scratches and I avoided applying it to anything below the top surface (e.g., inside the house). This process left areas where the brass powder was still visible and made everything look like aged antique gold that had been polished on the surface.

I was much happier with these results. It wasn’t exactly what I had set out to do, but they led to more experimentation. The mix of brass powder, iridescent bright gold paint, and gold leaf wax added some complexity to the resin pieces that really shines in person (pun intended).